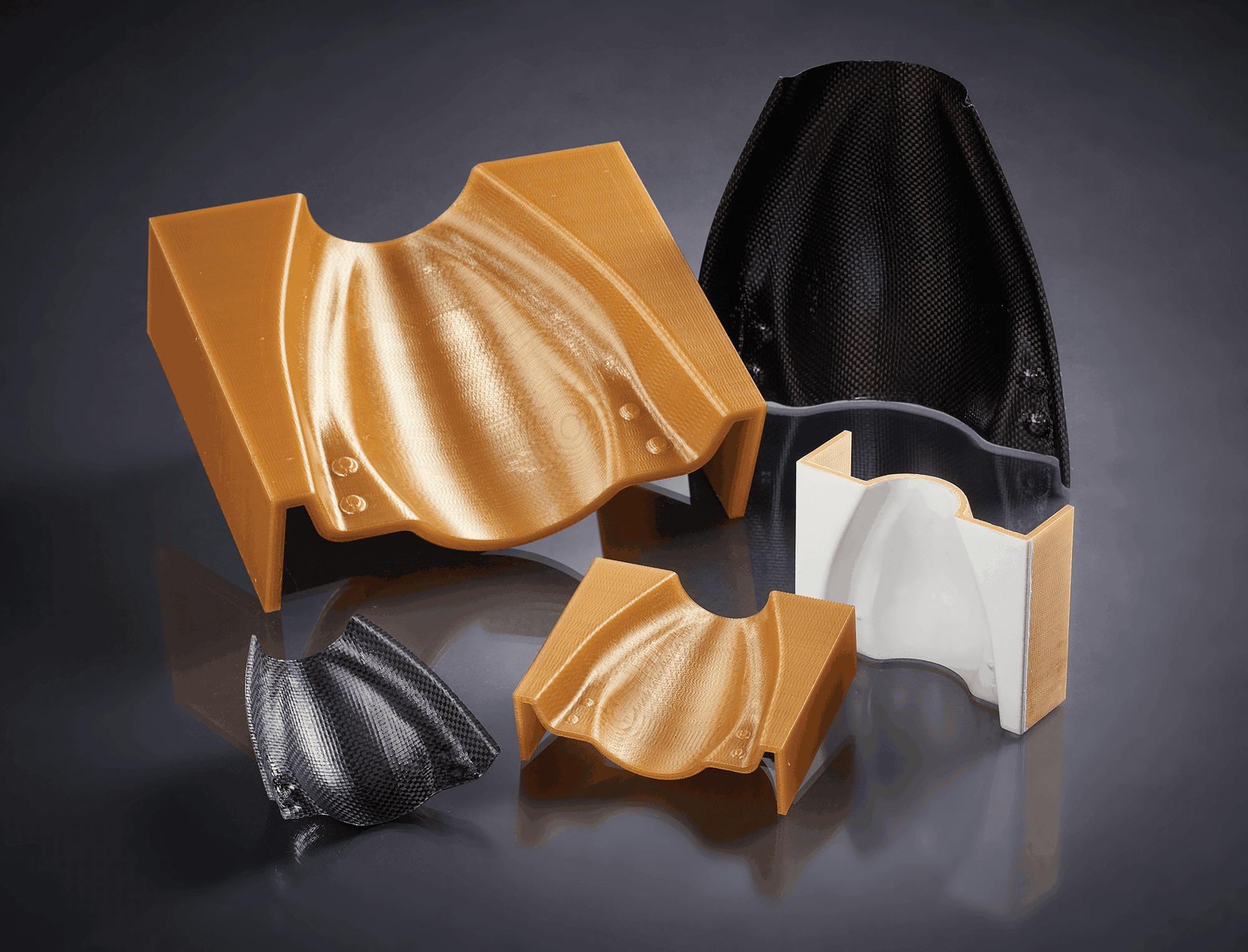

At Baltic3D you get manufacturing capacity of 16 industrial 3D printers. We print and delivers your end-products in as fast as 48 hours. Our main advantage is the the large build size and a choice of high-performance thermoplastics, such as carbon fiber-reinforced nylon, ULTEM™, ANTERO™, as well as more common PC-ABS or ASA.

Volume manufacturing

With 16 industrial 3D machines, Baltic3D can deliver up to 40 000 hours of manufacturing per year. Fortus 450 and 900 machines are built for precision, repeatability and high performance materials, required by Industrial applications.

Large Build size - up to 1 meter

Manufacturing large size components is a huge advantage of Baltic3D. With the largest FDM 3D machines on the market - Stratasys Fortus 900, we can rapidly manufacture components as large as 914 x 609 x 914 mm.

ULTEM™ polymer resin

ULTEM™ 1010 is the highest heat- and chemical-resistant polymer with exceptional tensile strength. It is food- and medical-certified material.

ULTEM™ 9085 resin is approved for transportation interior parts (buses, trains, boats, etc.)

Drone industry praises ergonomic and lightweight properties achieved by ULTEM™ 1010

It allows to reduce weight, minimize part count and design organic shapes. ULTEM™ resin provides highest tensile and flexural strength.

Buses, trains, emergency vehicles, sports cars require interior upgrades

Electronic housings, handles, disinfection trays and more can be printed with ULTEM™ 1010, and used as end-products.

“Our Aerospace customers in the Baltics and Germany require Interior parts with high precision, toughness and fire-smoke-toxicity certification achieved by ULTEM 1010. FDM technology provides us with reliability, speed and high capacity, critical when it comes to High performance end-products.

— Janis Jatnieks, CEO